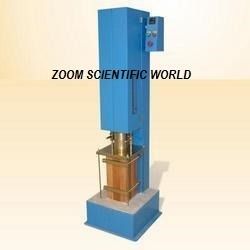

Bitumen Centrifuge Extractor

Product Details:

- Usage industries

- Product Type Centrifuge Extractor

- Color Blue

- Voltage 220 Volt (v)

- Material Stainless Steel

14 INR/Unit

X

Bitumen Centrifuge Extractor Price And Quantity

- 14 INR/Unit

- 1 Unit

Bitumen Centrifuge Extractor Product Specifications

- Centrifuge Extractor

- industries

- Stainless Steel

- Blue

- 220 Volt (v)

Bitumen Centrifuge Extractor Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 100 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- All India

Product Description

Zoom provides you the best quality products and a whole new range of products .Being a quality driven organization, we are actively committed towards offering Bitumen Centrifuge Extractor. Being a prominent firm, we are affianced in providing our clients with a distinct assortment of Bitumen Centrifuge Extractor. The offered product comes in numerous capacity and sizes as per its application in industries. The components and raw material used in manufacturing this product is sourced from the authentic vendors of the market. Considering various requirements of our clients, we offer the entire range in various configurations to choose from. The offered product is widely praised by our clients for its precise design and cost-effectiveness.Precision and Reliability for Industrial Testing

The Bitumen Centrifuge Extractor delivers precise extraction of bitumen from samples, ensuring reliable results in road construction and civil engineering projects. With its stainless steel structure and high-strength, break-resistant yarn, it guarantees longevity and consistent performance even in demanding environments. Its optimal twist and yield make it highly efficient for rigorous industrial analyses.

User-Friendly Design with Enhanced Durability

Designed with usability in mind, the extractors lightweight and robust build ensures ease of handling and transport. Its durable construction, coupled with a safe operating voltage of 220V, suits large-scale and repetitive testing scenarios. The blue, corrosion-resistant exterior ensures long-term serviceability in diverse industrial settings.

FAQs of Bitumen Centrifuge Extractor:

Q: How does the Bitumen Centrifuge Extractor function in material testing?

A: The Bitumen Centrifuge Extractor operates by spinning samples at high speed to effectively separate bitumen from aggregate materials. This process ensures accurate measurement of bitumen content for quality control in construction and industrial applications.Q: What benefits does the stainless steel construction provide?

A: Stainless steel construction offers excellent resistance to corrosion and wear, ensuring the extractors longevity, hygienic operation, and reliable performance even under harsh industrial conditions.Q: When should you use this extractor in your industrial workflow?

A: It is best utilized during the quality control phase of road construction, asphalt production, or any project requiring precise determination of bitumen content in sample materials.Q: Where is the Bitumen Centrifuge Extractor typically used?

A: This extractor is commonly deployed in laboratories, construction sites, and industrial facilities involved in material analysis, particularly within the road, civil engineering, and infrastructure sectors.Q: What is the process for operating the centrifuge extractor?

A: Place the prepared sample into the stainless steel chamber, secure the lid, and activate the unit. The centrifuge uses high-speed rotation to separate bitumen, which is then collected for measurement and analysis.Q: How does the extractors high strength and break-resistant features benefit users?

A: The extractors high strength and break-resistant design ensure safe, long-term operation even under demanding use, minimizing maintenance needs and reducing the risk of mechanical failure.Q: What industrial standards does this product meet as an exporter and manufacturer from India?

A: Manufactured in India, this extractor complies with stringent industry standards, ensuring reliable performance, export suitability, and compatibility with global material testing protocols.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email