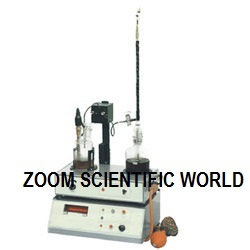

Bulk Density Apparatus

Product Details:

- Voltage 230 Volt (v)

- Usage Laboratory

- Material Mild Steel

- Color Purpal And White

- Product Type Apparatus

125 INR/Unit

X

Bulk Density Apparatus Price And Quantity

- 1 Unit

- 125 INR/Unit

- 2 or 3 (as per requirement)

- 100 ± 5 RPM

- 50 ml, 100 ml, 250 ml

- Continuous and preset

- ISI/ISO Standards

Bulk Density Apparatus Product Specifications

- Laboratory

- Mild Steel

- Purpal And White

- Apparatus

- 230 Volt (v)

- 2 or 3 (as per requirement)

- 100 ± 5 RPM

- 50 ml, 100 ml, 250 ml

- Continuous and preset

- ISI/ISO Standards

Bulk Density Apparatus Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1000 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, Middle East, Central America, Eastern Europe, South America, Western Europe, Asia, North America, Africa

- All India

Product Description

Bulk Density Apparatus:- Specially designed to study,the packing down of powder beds of different pharmaceuticals and chemicals in the process of tablet manufacturing,capsule filling & cosmetics,Installed with an automatic device for preset of strokes.Gear driven Noiseless and strudy motor,also provided with an electronic timer,Elegantly designed for smooth operation electrically operated on 230V AC, 50 Hz. (b) ---do--- digital display model.Reliable Bulk Density Determination

Our Bulk Density Apparatus, crafted from mild steel, is engineered for accurate and repeatable determination of bulk density in powder and granular materials. It is ideal for laboratory use in educational, industrial, and research settings. The equipment offers versatile sample handling thanks to its interchangeable jars (available in 50 ml, 100 ml, and 250 ml sizes), making it suitable for various sample volumes.

Key Features and Compliance

This apparatus is available with either two or three jars based on your requirements. It operates at 230 Volt (v) and provides consistent rotational speed at 100 5 RPM, ensuring precise and reproducible results. With adherence to ISI/ISO quality standards, it delivers reliability and regulatory compliance for laboratory testing. The devices operation is designed to be continuous or preset for maximum efficiency.

FAQs of Bulk Density Apparatus:

Q: How do I use the Bulk Density Apparatus for laboratory testing?

A: Begin by selecting the appropriate jar size according to your sample (50 ml, 100 ml, or 250 ml). Load the sample into the jar, fix it in the apparatus, set the operation mode (continuous or preset), and allow the device to rotate at 100 5 RPM. The sample settles under controlled conditions, enabling accurate measurement of bulk density.Q: What types of samples can be tested with this apparatus?

A: The Bulk Density Apparatus is suitable for powders, granules, and similar particulate substances typically found in pharmaceutical, food, chemical, and industrial labs. It is designed for materials where determination of bulk density is critical for quality control and research.Q: When should I consider using two or three jars?

A: The choice between two or three jars depends on your testing throughput and sample requirements. Multiple jars allow simultaneous testing of different samples or replicate measurements, increasing efficiency in laboratories with high sample volumes.Q: Where is the Bulk Density Apparatus commonly used?

A: This apparatus is widely used in research laboratories, educational institutions, industrial quality control departments, and manufacturing facilities throughout India, where bulk density measurements are essential for material processing and development.Q: What is the benefit of the 100 5 RPM rotation for my results?

A: The consistent rotational speed of 100 5 RPM ensures that samples are uniformly compacted, reducing variability in measurements. This standardization guarantees reproducibility and accuracy, which are vital for comparative analysis and industrial compliance.Q: Does the apparatus meet any regulatory or quality standards?

A: Yes, the Bulk Density Apparatus complies with ISI/ISO standards, offering assurance of product quality and suitability for regulated environments. This compliance is crucial for laboratories requiring reliable and standardized results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email