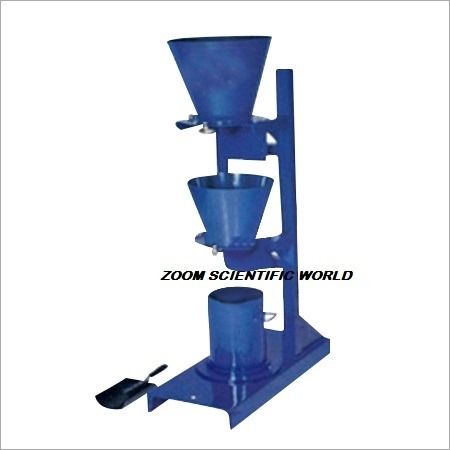

Dorry Abrasion-Testing-Machine

Product Details:

- Usage industries

- Product Type Testing-Machine

- Color Blue

- Voltage 220-240 Volt (v)

- Material Mild Steel

13 INR/Unit

X

Dorry Abrasion-Testing-Machine Price And Quantity

- 1 , Unit

- 13 INR/Unit

- 200 mm

- IS:2386 (Part IV)

- 25 mm

- 40 kg

Dorry Abrasion-Testing-Machine Product Specifications

- industries

- Blue

- Mild Steel

- 220-240 Volt (v)

- Testing-Machine

- 200 mm

- IS:2386 (Part IV)

- 25 mm

- 40 kg

Dorry Abrasion-Testing-Machine Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 100 , Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, Middle East, Central America, Eastern Europe, South America, Western Europe, Asia, North America, Africa

- All India

Product Description

Zoom provides you the best quality products and a whole new range of products .Being a quality driven organization, we are actively committed towards offering Dorry Abrasion-Testing-Machine. Being a prominent firm, we are affianced in providing our clients with a distinct assortment of Dorry Abrasion-Testing-Machine. The offered product comes in numerous capacity and sizes as per its application in industries. The components and raw material used in manufacturing this product is sourced from the authentic vendors of the market. Considering various requirements of our clients, we offer the entire range in various configurations to choose from. The offered product is widely praised by our clients for its precise design and cost-effectiveness.Efficient Abrasion Resistance Testing

The Dorry Abrasion-Testing-Machine streamlines the evaluation of aggregates and similar materials by providing precise abrasion resistance measurements. Its sizable steel abrasive disc and solid load capacity enable laboratories and manufacturers to conduct quality testing with minimal operator intervention. This machine is built to withstand daily industrial use, making it an indispensable tool for ensuring material performance and durability in construction projects.

Compliance and Industrial Application

Designed in accordance with IS:2386 (Part IV), the Dorry Abrasion-Testing-Machine assures conformity with established testing protocols in India. The equipment is ideally suited for aggregate testing labs, construction material suppliers, manufacturers, and educational institutions involved in material characterization. Its durable construction and straightforward operation allow seamless integration into existing industrial workflows.

FAQs of Dorry Abrasion-Testing-Machine:

Q: How does the Dorry Abrasion-Testing-Machine operate?

A: The machine uses a rotating abrasive disc, measuring 200 mm in diameter and 25 mm thick, to apply abrasion to test samples such as construction aggregates. During operation, the material sample is securely held, and abrasion is performed under controlled conditions, allowing for accurate assessment of material resistance.Q: What materials can be tested using this machine?

A: The Dorry Abrasion-Testing-Machine is primarily used to test aggregates and other construction materials for abrasion resistance, as specified in IS:2386 (Part IV). It is widely utilized in laboratories and industries concerned with civil engineering and construction quality assurance.Q: When is abrasion resistance testing required in construction projects?

A: Abrasion resistance testing is necessary when evaluating aggregates for use in roads, pavements, concrete, and related structures to ensure their durability and performance under friction and wear. This test helps predict how materials will perform over time and under stress.Q: Where is the Dorry Abrasion-Testing-Machine typically installed?

A: It is commonly found in material testing laboratories, universities, quality control departments of construction companies, and aggregate manufacturing facilities across India and other regions following IS standards.Q: What is the process for conducting a test on this machine?

A: A material sample is placed in the holder, the abrasive disc is set up, and the machine is powered on using the 220-240 Volt supply. The disc rotates to abrade the sample under a specified load (up to 40 kg), and the reduction in sample mass or changes in material characteristics are measured post-testing.Q: How does using this machine benefit material suppliers and contractors?

A: By delivering standardized, reliable abrasion resistance data, suppliers and contractors can verify the quality of aggregates. This helps in selecting appropriate materials for construction, reducing the risk of premature failures, and ensuring compliance with industry standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email