Magnetizing And Demagnetizing Solenoid

Product Details:

- Model No MDS-Series

- Core Components Copper Coil, Iron Core

- Power Source Electric

- Temperature Range 0C to 60C

- Feature Continuous and Intermittent Operation

- Measurement Range Up to 4000 Gauss

- Automation Grade Manual

101 INR/Piece

X

Magnetizing And Demagnetizing Solenoid Price And Quantity

- 1 Piece

- 101 INR/Piece

- Class F

- Tool Manufacturing, Workshop Maintenance, Magnetic Material Processing

- 1.5 Meter Power Cable

- 5 Seconds Per Cycle

- Powder Coated

- Heavy Duty Copper Winding

- Air-cooled

- Overload Protection

- Manual Switch Controls

- Single Phase

- Up to 95% RH

- Bench Mounted

Magnetizing And Demagnetizing Solenoid Product Specifications

- Up to 4000 Gauss

- Electric

- 0C to 60C

- Continuous and Intermittent Operation

- MDS-Series

- Copper Coil, Iron Core

- 10 kg to 90 kg (Depending on Size)

- Manual

- 1 kVA to 20 kVA

- High (1%)

- 300 mm x 150 mm x 200 mm to 1000 mm x 600 mm x 800 mm

- 50/60 Hz

- For magnetizing and demagnetizing ferromagnetic components

- Magnetizing and Demagnetizing Solenoid

- 230 V / 415 V AC

- Copper coil, Steel body

- Analog

- Class F

- Tool Manufacturing, Workshop Maintenance, Magnetic Material Processing

- 1.5 Meter Power Cable

- 5 Seconds Per Cycle

- Powder Coated

- Heavy Duty Copper Winding

- Air-cooled

- Overload Protection

- Manual Switch Controls

- Single Phase

- Up to 95% RH

- Bench Mounted

Magnetizing And Demagnetizing Solenoid Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 1000 Piece Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

Zoom is a esteemed manufacturer and exporter.

Magnetizing and Demagnetizing Solenoid -

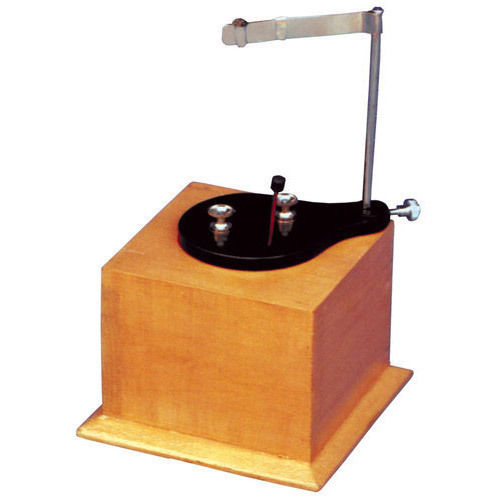

A helical coil 310 mm long of DCC copper wire mounted on a wooden board,

number of turns marked,

with one meter connecting cable, fuses, push switch compass & soft iron rod 350 x 10 mm.

Internal dia of coil 25 mm approx. For use on 230 V mains supply.

Reliable Air-Cooled Performance

This solenoid uses an air-cooled design for efficient performance and extended life of copper winding even under demanding conditions. The robust steel body and powder-coated finish ensure durability in workshop and industrial environments, while Class F insulation offers superior protection at operating temperatures ranging from 0C to 60C.

Versatile Applications Across Industries

Ideal for magnetizing and demagnetizing various ferromagnetic tools, components, and materials, the MDS-Series caters to tool manufacturing, workshop maintenance, and magnetic material processing. It delivers precise and repeatable results, making it a valuable asset for exporters, manufacturers, suppliers, traders, and wholesalers throughout India.

User-Friendly Manual Operation and Safety

Equipped with a straightforward manual control panel and analog display, this solenoid allows easy operation by technicians. Overload protection circuitry ensures safe operation during each five-second magnetizing or demagnetizing cycle, while the 1.5-meter power cable supports flexible bench mounting.

FAQs of Magnetizing And Demagnetizing Solenoid:

Q: How does the magnetizing and demagnetizing process work with the MDS-Series solenoid?

A: The process involves placing the ferromagnetic component within the solenoid coil, using the manual switch to activate magnetizing or demagnetizing. The copper coil generates a controlled magnetic field (up to 4000 Gauss) which magnetizes or neutralizes the part, typically within a five-second cycle.Q: What applications can the Magnetizing and Demagnetizing Solenoid be used for?

A: This equipment is suitable for tool manufacturing, workshop maintenance, and magnetic material processing. It is designed for magnetizing and demagnetizing a range of ferromagnetic components, such as tools, dies, and machine parts, ensuring they meet specific performance or safety specifications.Q: When should I use the continuous or intermittent operation modes?

A: Continuous operation is ideal for handling batches of small components, while intermittent operation is recommended for larger items or higher-power cycles. This prevents overheating and ensures operational safety, especially during extended use in high-capacity environments.Q: Where is the solenoid typically mounted during operation?

A: The solenoid is designed to be bench mounted, making it suitable for workshop settings and manufacturing floors. Its compact design and 1.5-meter power cable provide flexibility for installation and movement within the workspace.Q: What safety features are included in the MDS-Series solenoid?

A: For user protection, the solenoid incorporates overload protection and Class F electrical insulation. These features minimize risks from power surges, excessive temperatures, or unexpected loads, providing reliable operation within the rated voltage and temperature limits.Q: How is the equipment powered and controlled?

A: The solenoid operates on single-phase AC (230 V or 415 V), with frequency options of 50 or 60 Hz, and features manual switch controls. This setup provides precise operational control and easy adjustment for varying requirements.Q: What are the main benefits of using this solenoid in industrial applications?

A: Key advantages include fast five-second magnetizing/demagnetizing cycles, robust construction for longevity, high measurement accuracy (1%), adaptable voltage input, and a user-friendly interface. Together, these features support efficient, reliable, and safe processing of magnetic materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email