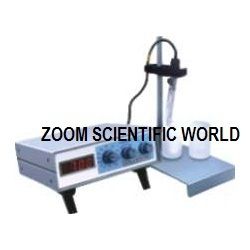

Motor Driven Disintegrator

Product Details:

- Product Type Driven Disintegrator

- Color White

- Material Mild Steel

- Voltage 110-220 Volt (v)

- Usage Industrial

1000 INR/Unit

X

Motor Driven Disintegrator Price And Quantity

- 1000 INR/Unit

- 1 Unit

- 150 x 120 mm

- Grinding, Crushing, Pulverising

- 4

- 2 HP

Motor Driven Disintegrator Product Specifications

- Driven Disintegrator

- White

- 110-220 Volt (v)

- Mild Steel

- Industrial

- 150 x 120 mm

- Grinding, Crushing, Pulverising

- 4

- 2 HP

Motor Driven Disintegrator Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1000 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Australia, Middle East, South America, Asia, Central America, Eastern Europe, North America, Africa

- All India

Product Description

Motor Driven Disintegrator: Laboratory size, hammer type, with H.P. heavy duty motor (single phase) 220 volts, 50C/S A.C. consisting of four steel hammers fixed to a disc 3 in dia 1 thick through which passes a shaft being revolved at 3000 R.P.M.The hammers are enclosed in a C.I. drum, the sides and upper surface of which are roughened. The inner surface is undulating. The lower part of drum is made of detachable, screen (sieves) of different mesh size (a) set of three sieves of coarse, medium and fine supplied. Hopper is made of heavy gauge m.s. sheet, Built on angle iron frame.Efficient Sample Preparation

Engineered for industrial applications, the Motor Driven Disintegrator ensures rapid and uniform grinding, crushing, and pulverizing of materials. Its sturdy mild steel build and 2 HP motor deliver consistent performance, making it a valuable asset for laboratories, research centers, and small manufacturing units that require precise sample processing.

User-Friendly Design

The disintegrator is equipped with a spacious hopper opening (150 x 120 mm), allowing for hassle-free material feeding. Its compatibility with 110220 volt power supplies ensures flexibility in diverse environments. The machines robust design guarantees minimal maintenance and long-term reliability for heavy-duty use.

FAQs of Motor Driven Disintegrator:

Q: How does the Motor Driven Disintegrator operate?

A: This machine operates by feeding solid materials through a 150 x 120 mm hopper. The contents are then subjected to grinding, crushing, or pulverising by the high-powered 2 HP motor, which ensures efficient and quick processing.Q: What types of materials can be processed with this disintegrator?

A: The Motor Driven Disintegrator is suitable for processing a range of solid samples, including minerals, chemicals, agricultural products, and dry food materials, making it versatile across various industrial and laboratory settings.Q: When should I use a motor driven disintegrator?

A: Use this equipment when your workflow requires rapid, consistent, and uniform grinding or crushing of materials. It is ideal for laboratory sample preparation, quality control, or small-batch production environments.Q: Where is the Motor Driven Disintegrator ideally used?

A: This machine is ideally used in laboratories, research institutions, and small-scale industrial units where reliable and efficient sample preparation is essential for analysis or production.Q: What is the benefit of the mild steel construction?

A: Mild steel provides the machine with strength, durability, and resistance to daily industrial wear and tear, ensuring a long operational lifespan even under robust usage.Q: How do I maintain the Motor Driven Disintegrator?

A: Regular cleaning of the hopper and grinding chamber, along with periodic inspection of the motor, is recommended. Always ensure that the machine is powered off before maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email