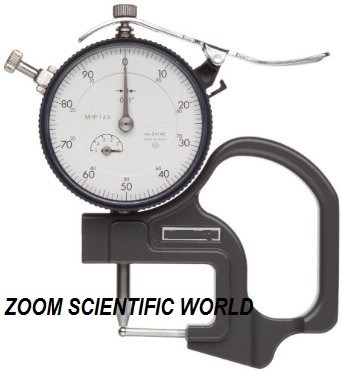

Thickness Gauges

Product Details:

- Usage Laboratory, Industrial

- Product Type Gauges

- Color Black And White

- Material Plastic And Stainless Steel

16 INR/Unit

X

Thickness Gauges Price And Quantity

- 1 Unit

- 16 INR/Unit

- Lightweight, typically under 300g

- 0.01 mm or Better (Depends on model)

- Suitable for indoor laboratory and industrial use

Thickness Gauges Product Specifications

- Black And White

- Gauges

- Laboratory, Industrial

- Plastic And Stainless Steel

- Lightweight, typically under 300g

- 0.01 mm or Better (Depends on model)

- Suitable for indoor laboratory and industrial use

Thickness Gauges Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 100 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- All India

Product Description

Zoom provides you the best quality products and a whole new range of products .Being a quality driven organization, we are actively committed towards offering Thickness Gauges. Being a prominent firm, we are affianced in providing our clients with a distinct assortment of Thickness Gauges. The offered product comes in numerous capacity and sizes as per its application in industries. The components and raw material used in manufacturing this product is sourced from the authentic vendors of the market. Considering various requirements of our clients, we offer the entire range in various configurations to choose from. The offered product is widely praised by our clients for its precise design and cost-effectiveness.Versatile Laboratory and Industrial Use

Thickness gauges are engineered for a broad range of applications, suitable for both laboratory analysis and industrial quality control. Their design facilitates consistent measurements across various materials, ensuring reliable data for research, production, and inspection activities. Lightweight construction enhances portability, making them an essential tool for professionals requiring quick and accurate thickness evaluation in different operating environments.

High Accuracy and Robust Material

With a resolution of 0.01 mm or better, these thickness gauges deliver precise measurements essential for quality assurance tasks. The use of plastic and stainless steel in construction ensures resistance to wear and corrosion, extending instrument longevity. This robust build allows the gauges to maintain reliability even during intensive use, making them a dependable choice for routine and critical applications.

FAQs of Thickness Gauges:

Q: How do I use a thickness gauge in an industrial or laboratory setting?

A: To use a thickness gauge, place its measuring surfaces gently on the material you wish to measure. Ensure the gauge is calibrated, then read the thickness value displayed with up to 0.01 mm resolution. These gauges are suitable for a variety of solid materials, including metals and plastics.Q: What materials can be measured with these thickness gauges?

A: Thickness gauges constructed from plastic and stainless steel can measure a wide range of materials such as metal sheets, plastic films, and other solid substrates commonly encountered in laboratory and production environments.Q: When should I employ a thickness gauge during my workflow?

A: Thickness gauges should be used during initial quality assessment, production-line checks, and final inspection stages to ensure material thickness meets required specifications. Their frequent use helps maintain quality standards and prevents costly errors.Q: Where are these thickness gauges typically utilized?

A: These gauges are regularly employed in laboratories, manufacturing facilities, quality control departments, and industrial workshops throughout India. Their versatile design makes them suitable for both onsite assessments and routine material testing.Q: What benefits do thickness gauges provide for exporters and manufacturers?

A: Exporters and manufacturers benefit from improved quality control, reduced material waste, and enhanced compliance with industry standards by using thickness gauges. Accurate thickness readings enable reliable product specification and process optimization.Q: Can these gauges be used for frequent measurements?

A: Yes, their lightweight build (under 300g) and durable construction allow for frequent, repetitive use without significant fatigue or instrument wear. This makes them practical for daily routines in high-volume production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email