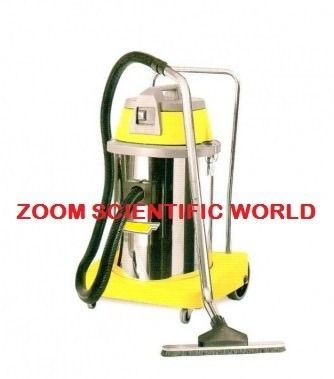

Vacuum Pump

Product Details:

- Color Silver And Black

- Product Type Pump

- Usage Industrial

- Voltage 110-220 Volt (v)

- Material Stainless Steel

X

Vacuum Pump Price And Quantity

- 1 Unit

- <60 dB

- up to 0.05 mbar

- Standard Vacuum Pump Oil

- Single/Three Phase options

- 0.5 HP to 2 HP (depending on model)

Vacuum Pump Product Specifications

- Industrial

- Pump

- Silver And Black

- 110-220 Volt (v)

- Stainless Steel

- <60 dB

- up to 0.05 mbar

- Standard Vacuum Pump Oil

- Single/Three Phase options

- 0.5 HP to 2 HP (depending on model)

Vacuum Pump Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1000 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Middle East, Central America, South America, Asia, Eastern Europe, North America, Australia, Africa

- All India

Product Description

Vacuum Pump:- Motor driven,oil sealed pump mounted on heavy base.It is driven by V-belt at speed upto 400 RPM.Choice of single and double stage available creating ultimate vacuum of 0.01mm of Hg. colimn and 0.00mm of Hg. column respectively.The pump is to work on 220v AC 50Hz single phase.Capacities available are:- Capacity Motor HP (a) 25 lit./min. 0.25 (b) 50 lit./min. 0.25 (c) 75 lit./min. 0.25 (d) 100 lit./min. 0.50 OPTIONALS (Extra Cost) (i) Vacuum gauge. (ii) Belt guard. (iii) Moisture trap. (iv) Non-return valve. (v) Air blast.Reliable and Efficient Vacuum Generation

This vacuum pump is engineered to deliver consistent vacuum pressure up to 0.05 mbar, ideal for laboratories, manufacturing units, and research facilities. With its durable stainless steel construction and quiet operation below 60 dB, it ensures a safe and efficient working environment. Easy compatibility with standard voltage options and threaded fittings makes installation straightforward, while the use of standard vacuum pump oil ensures low maintenance and long operational life.

Flexible Motor Power and Voltage Options

The vacuum pump is available in multiple motor power configurations, ranging from 0.5 HP to 2 HP. It works on a broad voltage range (110220 V), accommodating both single and three-phase power supplies. This flexibility allows users to match the pump to their specific requirements, making it a versatile choice for various industrial and scientific applications.

FAQs of Vacuum Pump:

Q: How does the vacuum pump achieve a maximum vacuum of up to 0.05 mbar?

A: The vacuum pump employs a high-efficiency motor and precision-engineered components to reduce air pressure within a sealed environment, achieving a vacuum as low as 0.05 mbar. Its robust design and optimal sealing prevent leaks and ensure reliable vacuum generation for demanding applications.Q: What is the appropriate application for this vacuum pump?

A: This vacuum pump is suitable for industrial and laboratory use, especially where precise vacuum control is required. Common applications include filtration, degassing, freeze drying, and supporting scientific instruments that require controlled atmospheric conditions.Q: When should I replace the vacuum pump oil?

A: It is recommended to check and replace the vacuum pump oil regularly, in accordance with the manufacturers guidelines or after extended periods of operation. Clean, high-quality oil is essential for optimal performance and to avoid pump wear.Q: Where should the vacuum pump be installed for best performance?

A: Install the pump on a flat, stable surface in a well-ventilated area, away from excessive moisture and heat. Ensure easy access to the threaded inlet and outlet connections for smooth integration into your vacuum system.Q: What benefits does stainless steel construction offer for this pump?

A: The stainless steel body provides superior resistance to corrosion, chemical exposure, and mechanical wear, making the pump highly durable and well-suited for rigorous industrial or laboratory environments.Q: How quiet is the vacuum pump during operation?

A: The vacuum pump operates at a noise level below 60 dB, making it suitable for environments where minimizing noise is important, such as laboratories and workspaces requiring concentration.Q: What accessories or connections are required for setup?

A: The pump features standard threaded fittings on both inlet and outlet, enabling straightforward connection to hoses or vacuum systems. No special accessories are needed, but ensure that appropriate vacuum-rated hoses and clamps are used to maintain system integrity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email