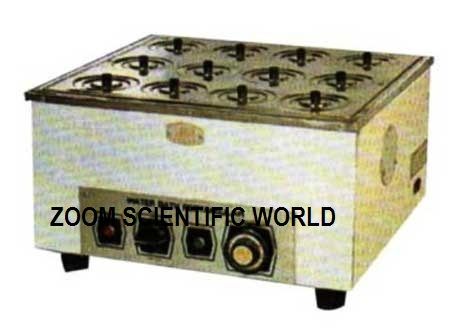

Water Deionzation Apparatus

Product Details:

- Usage Laboratory, Industrial

- Color Blue And Red And White And Black

- Product Type Deionzation Apparatus

- Material Mild Steel

- Capacity 30 to 50 Lit Kg/hr

127 INR/Unit

X

Water Deionzation Apparatus Price And Quantity

- 1 Unit

- 127 INR/Unit

Water Deionzation Apparatus Product Specifications

- Laboratory, Industrial

- 30 to 50 Lit Kg/hr

- Mild Steel

- Deionzation Apparatus

- Blue And Red And White And Black

Water Deionzation Apparatus Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 100 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America, Africa

- All India

Product Description

Water Deionization Apparatus:- The plant consists of One Exchanger column containing cotion Exchanger Resin.One anion exchanger column containing anion exchanger resin.plant is mounted on M.S stand with assembly of valves and tubing.

One conductivity meter with cell to monitor the ionised solids of purified water and thus control the functions of demineralisation.The meter is direct reading having reading heavy range 0.40 microns/cm.

(a) Cao. or flow rate 30 to 50 lt/hr.

(b) Cap. or flow rate 75 to 100 lt/hr.

Advanced Water Purification Technology

Our apparatus employs state-of-the-art deionization techniques to remove dissolved salts and impurities, ensuring consistent water purity for laboratory and industrial uses. The robust mild steel construction guarantees longevity, while the diverse color options cater to different facility aesthetics.

Adaptable for Multiple Applications

Designed for flexibility, this water deionizer operates seamlessly in laboratories for analytical processes and in industrial settings for equipment maintenance, chemical production, and more. Its capacity range suits both small-scale experiments and larger operational demands.

Serving Indias Diverse Water Treatment Needs

As an established exporter, manufacturer, supplier, trader, and wholesaler, we provide trusted solutions throughout India. Our responsive support and efficient distribution help businesses and research facilities maintain the highest water quality standards.

FAQs of Water Deionzation Apparatus:

Q: How does the water deionization apparatus work in laboratory and industrial settings?

A: This apparatus uses ion exchange processes to remove mineral ions from water, producing high-purity, deionized water. The system is tailored to handle capacities between 30 to 50 liters per kilogram per hour, making it ideal for both laboratory analyses and various industrial operations.Q: What are the main benefits of using a deionization apparatus made from mild steel?

A: Mild steel ensures structural durability, corrosion resistance, and long equipment lifespan. This makes the deionization apparatus well-suited for continuous use in demanding laboratory or industrial environments.Q: When is it necessary to use deionized water in laboratories or industries?

A: Deionized water is essential when impurities, minerals, and ions can interfere with processes or experimental results. Laboratories use it in chemical and biological tests, while industries need it for manufacturing, rinsing, or cooling sensitive equipment.Q: Where is the water deionization apparatus typically installed?

A: This apparatus is generally installed in laboratories conducting chemical research or testing, as well as in industrial facilities such as manufacturing plants or processing units where pure water is a necessity.Q: What is the process for operating the water deionization equipment?

A: To operate, feed water is passed through the mild steel unit where it flows through ion exchange resins that remove unwanted ions. The deionized water is then collected for use. Regular maintenance, including resin regeneration or replacement, ensures optimal performance.Q: How can customers in India source this deionization apparatus?

A: Customers across India can obtain the apparatus directly from us as we offer extensive export, manufacture, supply, trading, and wholesale services. Our professional team provides support for installation, training, and after-sales service.Q: What kinds of applications benefit most from this water deionization system?

A: Applications benefitting from this system include analytical chemistry, electronics manufacturing, pharmaceutical preparation, laboratory research, and any industry where water purity impacts outcomes or equipment longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email