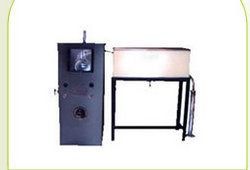

Engler Viscometer Apparatus

Product Details:

- Usage Laboratory

- Product Type Viscometer Apparatus

- Color Silver

- Voltage 220 Volt (v)

- Material Stainless Steel

140 INR/Unit

X

Engler Viscometer Apparatus Price And Quantity

- 1 Unit

- 140 INR/Unit

- Polished Stainless Steel

- 100 ml

- IS 1448, ASTM D490 and IP 212 standards

- Yes, for easy emptying

- Approx. 65 mm

- 0°C to 360°C (included)

Engler Viscometer Apparatus Product Specifications

- Silver

- Viscometer Apparatus

- Stainless Steel

- 220 Volt (v)

- Laboratory

- Polished Stainless Steel

- 100 ml

- IS 1448, ASTM D490 and IP 212 standards

- Yes, for easy emptying

- Approx. 65 mm

- 0°C to 360°C (included)

Engler Viscometer Apparatus Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 10 Unit Per Week

- 1 Seconds

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- All India

Product Description

Used for determining the Viscosity of lubricating and fuel oils in accordance with continental emulsions.It consists of Stainless steel water bath having oil cup with double walled lid.The water bath with stirring device mounted on stand . A thermometer clip to the water bath and the oil cup lid has a thermometer socket. The bath is fitted with 500 watts heater . It is supplied with wooden or ebonite valve to fit jet (without glaswares). Can operate on 220 Volts AC mains.

- Engler Viscometer Gas Heated Modal Without burner.

- Engler Viscometer Electric heated without any control.

- Engler Viscometer electric heated with separate energy

- Regulator control.

- Engler Viscometer electric heated with copper coil type

- Voltage varric.

- Engler Viscometer electric heated with digital

- Temperature controller cum indicator.

Optional Accessories:

- Ebonite or wooden valve

- Flask 200ml capacity

- Polished wooden case.

- Thermometer 23C or 24C or 25C any one.

Premium Build for Laboratory Reliability

With a corrosion-resistant stainless steel bath and robust construction, the Engler Viscometer Apparatus is engineered for intensive laboratory use. The design ensures long operational life and precision in viscosity measurement, making it ideal for both educational and industrial environments.

User-Friendly Operation and Maintenance

The apparatus features a conveniently placed drainage valve for simple emptying and cleaning post-experiment, reducing downtime between tests. The included thermometer slot caters to a wide range of temperatures (0C to 360C), adapting to diverse petroleum samples and experimental requirements.

Globally Recognized Standard Compliance

This viscometer strictly complies with IS 1448, ASTM D490, and IP 212 standards, guaranteeing accuracy and acceptance in academic, commercial, and regulatory laboratories. Users can trust the reported results for consistency and global comparability.

FAQs of Engler Viscometer Apparatus:

Q: How does the Engler Viscometer Apparatus determine viscosity?

A: The Engler Viscometer measures the time taken by 100 ml of oil to flow through a standardized orifice at controlled temperatures. This process provides a direct comparison to the flow time of water, yielding Engler viscosity values essential in petroleum analysis.Q: What standards are met by the Engler Viscometer Apparatus?

A: The instrument adheres to IS 1448, ASTM D490, and IP 212 standards, ensuring it meets industry protocols for precision and reliability during viscosity testing in laboratories.Q: When should the drainage valve be used during the testing process?

A: The drainage valve is typically used after completing the viscosity test. It enables safe and convenient emptying of the stainless steel bath, helping maintain cleanliness and preparing the apparatus for subsequent experiments.Q: Where is the Engler Viscometer best suited for use?

A: This viscometer is ideally suited for laboratory environments such as educational institutions, research centers, industrial quality control departments, and companies involved in petrochemical testing and product development.Q: What are the benefits of the stainless steel bath material?

A: Polished stainless steel offers excellent corrosion resistance, durability, and hygienic maintenance. This ensures reliable results, minimizes contamination risks, and supports longevity of the apparatus even with repeated usage.Q: How is the temperature monitored during viscosity measurement?

A: A thermometer with a range of 0C to 360C can be inserted directly into the apparatus, allowing users to monitor and control the temperature accurately throughout the testing process for optimal measurement conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email