Soxhlet Extraction

Product Details:

- Product Type Extraction

- Material Stainless Steel

- Color White And Black

- Voltage 220 - 240 Volt (v)

- Usage Laboratory Use

149 INR/Unit

X

Soxhlet Extraction Price And Quantity

- 1 Unit

- 149 INR/Unit

- Ceramic Wool

- Indoor Laboratory

- Powder Coated Iron

- Nichrome Wire

- Over Temperature Protection

- Borosilicate 3.3

- Petroleum Ether, Hexane, Ethanol, etc.

- Allihn Glass Condenser

Soxhlet Extraction Product Specifications

- 220 - 240 Volt (v)

- Laboratory Use

- Extraction

- White And Black

- Stainless Steel

- Ceramic Wool

- Indoor Laboratory

- Powder Coated Iron

- Nichrome Wire

- Over Temperature Protection

- Borosilicate 3.3

- Petroleum Ether, Hexane, Ethanol, etc.

- Allihn Glass Condenser

Soxhlet Extraction Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 100 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Central America, Eastern Europe, Middle East, South America, Asia, North America, Australia, Africa

- All India

Product Description

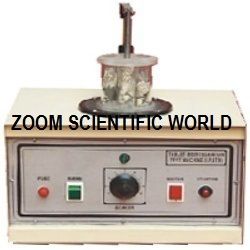

Soxhlet Extraction- Heater Mantle Type :

- Unit of three or six. Available in different capacities.

- Hot Plate Type :

- Tis heater is used to heat soxhlet flasks and it consists of a mild steel housing. Unit of three or six. Three or six hot plates of dia 4 1/2" are mounted on top of the housing and can be operated by individual.

- a) ON/OFF switch

- b) Rotary switch

- c) Energy regulator as per requirements.

- Mild steel housing has two rods with two adjustable cross rods on which the glass apparatus can be fixed.

- Electrically operated on 220 / 230 volts AC mains with max. power rating of 900 watts.

- The apparatus is supplied without glass parts.

- Glass Parts :

- Complete with one flask and bulb condenser with interchangeable joints. Different capacities.

Efficient Laboratory Extraction

The Soxhlet Extraction apparatus streamlines the process of extracting soluble compounds from various solids, ensuring thorough and repeatable results. Its continuous reflux design allows extended interactions between solvent and sample, maximizing analyte recovery without requiring large solvent volumes. Suitable for a variety of common laboratory solvents, this classic method is a trusted standard for purity analysis and sample preparation.

High-Quality, Safe Construction

Made from borosilicate 3.3 glass, this Soxhlet Extraction system is highly resistant to chemical corrosion and thermal shock. The inclusion of ceramic wool insulation and an Allihn glass condenser provides both operational safety and efficient condensation. Built to withstand rigorous laboratory environments, it operates at 220240 Volt, making it compatible with most laboratory infrastructure.

Applications Across Industries

Whether used in chemical testing, quality control, or research, Soxhlet Extraction is indispensable for fat, oil, or pesticide residue analysis. The system is ideal for sample preparation in food and pharmaceutical laboratories, ensuring the reliability of subsequent analytical procedures. Its versatility with different solvents further broadens its application across diverse scientific disciplines.

FAQs of Soxhlet Extraction :

Q: How does a Soxhlet Extraction apparatus operate in the laboratory?

A: A Soxhlet Extraction apparatus operates by continuously washing solid samples with a chosen solvent, such as petroleum ether, hexane, or ethanol. The solvent is heated to reflux, evaporates, condenses in the Allihn glass condenser, and repeatedly siphons through the sample, efficiently extracting desired compounds.Q: What types of samples and solvents are compatible with this Soxhlet Extraction apparatus?

A: The Soxhlet extractor is compatible with a wide range of solid samples, commonly used for extracting fats, oils, or pesticides from plant or food matrices. Recommended solvents include petroleum ether, hexane, ethanol, and other organic solvents suited to the target analyte.Q: When should I use the Soxhlet Extraction method over other extraction techniques?

A: Soxhlet Extraction is preferred when high extraction efficiency is needed and the target compounds are only moderately soluble in the selected solvent. It is especially useful for exhaustive extraction of analytes from complex solids without excessive solvent consumption.Q: Where is the Soxhlet Extraction apparatus best utilized?

A: This apparatus is best suited for indoor laboratory environments with appropriate power supply (220240 Volt), such as chemical, pharmaceutical, and food testing laboratories, as well as research institutions and quality control labs.Q: What is the benefit of using borosilicate 3.3 glass in Soxhlet extraction?

A: Borosilicate 3.3 glass offers high chemical durability, resistance to thermal shock, and ensures the apparatus can withstand repeated heating-cooling cycles in solvent extraction, thus ensuring longevity and reliable experimental results.Q: How does insulation with ceramic wool improve extractor safety?

A: Ceramic wool insulation minimizes heat loss and reduces the external temperature of the apparatus, decreasing the risk of accidental burns during operation and improving overall laboratory safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email