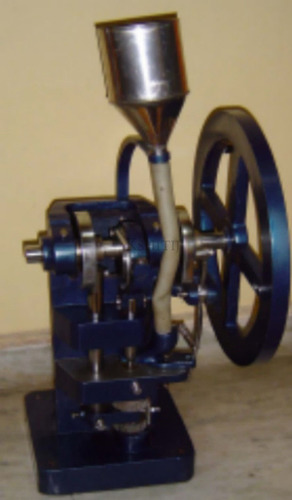

Tablet Machine

Product Details:

- Voltage 110-220 Volt (v)

- Material Mild Steel

- Color Blue And Silver

- Product Type Machine

- Usage Laboratory

101 INR/Unit

X

Tablet Machine Price And Quantity

- 101 INR/Unit

- 1 Unit

- 10

- Manual

- 6 Ton

- 6 mm to 12 mm

- Overload Protection, Emergency Stop

- Powder Coated

- Low

- Tabletting of powder for research and production

- 6 mm

Tablet Machine Product Specifications

- Mild Steel

- 110-220 Volt (v)

- Machine

- Laboratory

- Blue And Silver

- 10

- Manual

- 6 Ton

- 6 mm to 12 mm

- Overload Protection, Emergency Stop

- Powder Coated

- Low

- Tabletting of powder for research and production

- 6 mm

Tablet Machine Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 1000 Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe, Australia, Middle East, Central America, South America, Asia, Eastern Europe, North America, Africa

- All India

Product Description

Tablet Machine Hand Operated: Single punch for making tablets upto 1000mg and as per size of the punch 6mm. Automatic compression and ejection devise with each revolution of the wheel drive, automatic feed and removal of tablets. Built on heavy cast body with acentric pressure system. Stainless steel hopper provided and connected by a rubber tube. Easy setting for thickness and hardness of tablets with nuts locknuts, set of two spanners provided as necessary tool die. Heavy duty.Efficient Tablet Compression

This Tablet Machine provides precise and reliable compression for powdered materials, producing tablets with uniform dimensions. Its robust steel structure and powder-coated finish ensure durability, making it ideal for laboratory and industrial environments. The ability to process up to ten stations at once significantly increases productivity.

Safety and Operating Features

Equipped with overload protection, emergency stop, and a safety guard, the machine emphasizes user safety during operation. The manual lubrication system facilitates straightforward maintenance, while low-noise emissions contribute to a comfortable workspace.

Versatile Laboratory Usage

Designed for both research and small-scale production, the versatile power requirements (110220V) and adjustable tablet diameter make this tablet press suitable for varied applications in academic, pharmaceutical, and chemical laboratories.

FAQs of Tablet Machine:

Q: How does the Tablet Machine operate and what applications does it support?

A: The Tablet Machine compacts powder into solid tablets by exerting up to 6 tons of pressure. It is typically used in laboratory research and small production runs, suitable for academic, pharmaceutical, and chemical applications.Q: What are the supported tablet dimensions?

A: The machine supports tablet diameters from 6 mm to 12 mm, with a maximum tablet thickness of 6 mm, allowing flexibility for various formulations and sample requirements.Q: What safety features are included in this tablet press?

A: It incorporates overload protection to guard against excessive mechanical stress, an emergency stop for immediate shutdown, and a physical safety guard to shield operators during use.Q: How is the machine maintained during operation?

A: Manual lubrication ensures the moving components remain in optimal condition, enabling consistent operation and extending the lifespan of the device.Q: Where is this Tablet Machine best utilized?

A: It is best suited for laboratory settings and smaller-scale production environments where precise, reliable tablet formation is required.Q: What is the noise level during operation?

A: The machine operates at a low noise level, promoting a quiet and productive workspace.Q: What are the power supply requirements?

A: It runs efficiently on a standard 110-220 volt power supply, suitable for various laboratory and industrial facilities in India and global markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email