Tar Viscometer

Product Details:

- Usage Laboratory

- Product Type Viscometer

- Color Silver

- Voltage 230 Volt (v)

- Material Stainless Steel

150 INR/Unit

X

Tar Viscometer Price And Quantity

- 150 INR/Unit

- 1 , Unit

- Stainless Steel

- Heavy Duty Metal Stand

- Brass

- Manual

- IS 1206, ASTM D490

- Bituminous Mixture and Tar Viscosity Testing

- Integrated Funnel

- Benchtop

- Up to 500 W

- 50 ml

Tar Viscometer Product Specifications

- Silver

- Laboratory

- Viscometer

- 230 Volt (v)

- Stainless Steel

- Stainless Steel

- Heavy Duty Metal Stand

- Brass

- Manual

- IS 1206, ASTM D490

- Bituminous Mixture and Tar Viscosity Testing

- Integrated Funnel

- Benchtop

- Up to 500 W

- 50 ml

Tar Viscometer Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 10 , Unit Per Week

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

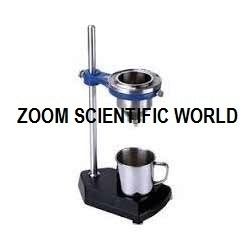

Determining the Viscosity of cut back Bitumen and road oil. It consists bath with cup of 10mm or 4mm erific and sleeve stirrer with ball lifting clip and ball. The assembly is kept on suitable stand with leveling screws. Suitable to operate on 220 Volts AC mains.- Electric heated (without control)

- Electric heated with separate energy regulator control.

- Electric heated with solid state electronic regulator.

- Electric heated with voltage varric copper coil type.

- Electric Heated with digital temperature controller cum indicator.

- Multiple Tar Viscometer for 6 test cups with thermostat control & FHP electric motor stirrer.

Optional Accessories :

- Spare silver plated orifice cup 10 mm or 4 mm.

- Flask receiver 100 ml capacity.

- Polished carrying wooden case.

- Thermometer 8C.

Precision Viscosity Measurement for Bitumen and Tar

Designed for laboratory usage, the Tar Viscometer delivers highly accurate measurements of bituminous mixture and tar viscosity. Made from stainless steel and brass, its construction ensures both durability and consistent results. Compliance with rigorous IS 1206 and ASTM D490 standards guarantees repeatable, industry-accepted data, essential for material quality checks and research.

Sturdy Construction for Reliable Lab Performance

Built with a heavy-duty metal stand and robust components, this viscometer remains stable during testing, preventing unwanted vibrations or movement. The integrated funnel design aids easy and mess-free sample introduction, while the 50 ml brass cup ensures reliable test volumes. Suitable for benchtop installation, it is ideal for busy laboratory environments.

Trusted Compliance for International Standards

Meeting IS 1206 and ASTM D490 standards, the Tar Viscometer provides results that are globally recognized. Such compliance is vital for laboratories involved in materials certification, asphalt and road testing, and industry-specific research. The confidence in test outcomes supports both domestic and export quality validations.

FAQs of Tar Viscometer:

Q: How do you use the Tar Viscometer in a laboratory setting?

A: To use the Tar Viscometer, install it securely on a benchtop using its heavy-duty metal stand. Preheat the instrument if required, add the tar or bituminous sample into the integrated funnel, and use the 50 ml brass test cup to collect the flow. Operation is straightforward and follows IS 1206 and ASTM D490 protocols for accurate viscosity measurement.Q: What materials can be tested with this Tar Viscometer?

A: The Tar Viscometer is specifically designed for evaluating the viscosity of bituminous mixtures and tar. It can be utilized for testing materials used in road construction, pavement layers, and quality control of bitumen and other similar products as required by IS 1206 and ASTM D490.Q: When should the Tar Viscometer be calibrated or maintained?

A: For consistent accuracy, calibrate the Tar Viscometer in accordance with your laboratorys schedule or after significant use, following standard laboratory procedures. Routine cleaning of the stainless steel and brass components after each test ensures reliable results and long equipment life.Q: Where should the Tar Viscometer be installed in a laboratory?

A: The viscometer is designed for benchtop installation. It should be placed on a stable, vibration-free surface in a well-ventilated laboratory area, allowing safe and easy access to electrical supply (230 Volt) and sufficient workspace for sample handling.Q: What are the benefits of using a standard-compliant Tar Viscometer?

A: Using a viscometer compliant with IS 1206 and ASTM D490 ensures that viscosity measurements meet international norms. This leads to trustworthy data for product validation, research, and quality assurance, and is essential for both domestic and global materials certification.Q: What process does the Tar Viscometer follow to measure viscosity?

A: The viscometer measures viscosity by timing the flow of a specific volume (50 ml) of heated tar or bituminous sample through an orifice, collected in a brass test cup. The flow time, under controlled temperature and using the integrated funnel, directly correlates with the materials viscosity.Q: How does the integrated funnel design enhance sample testing?

A: The integrated funnel in the Tar Viscometer simplifies pouring and minimizes spillage, enabling clean, efficient, and accurate introduction of the sample into the testing chamber. This feature improves both user safety and measurement reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email